Our Power Transmission Pulling Rope made by UHMWPE or Spectra® fiber. An

innovative new high performance pulling rope that is UV resistant, lightweight

and ultra low stretch.

JINLI Power Transmission Pulling Rope made from ultra high molecular weight polyethylene fibers. It’s the strongest natura synthetic fiber in the world. Now, most of people hear about synthetic rope instead of wire rope and working better than it. The world has changed a lot last century, we also consider synthetic rope how to working on puling. It has lower weight, increase safety, and operate faster.

1.Extreme strength-to-weight ratio

2.Lightweight and flexible for easy handing

3.Safer than wire ( low recoil)

4.Slimmer synthetic rope maintains higher WLL

5.Ultra low stretch, UV resistant, lightweight pulling rope

6.Dual factory installed pulling eyes

7.Does not absorb water, no rope rot

8.Traceable ID tags

| Fibre Type | Density | Sensitive to | Resistant to | Melting Point | Elongation at Break |

| UHMWPE | 0.97 g/cm3 | Strong oxidising agents, chlorosulphonic & nitric acids at high temperatures |

Most acids, alkalis, alcohols, esters, organic solvents & bleaches |

152°C | 3.5% |

| Polyester | 1.38 g/cm3 | Alkalis, phenolic compounds, sulphuric acid |

Most organic acids &solvents & oxidising agents |

255°C | 15% |

| Nylon | 1.14 g/cm3 | Acids & strong oxidising agents |

Alkalis & organic solvents |

220°C | 23% |

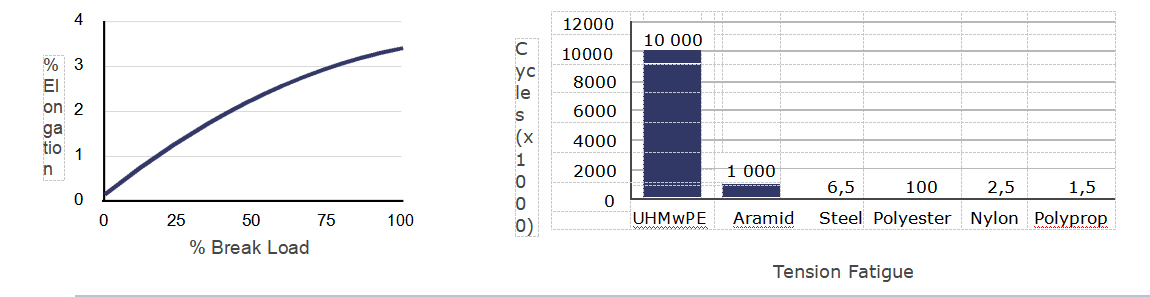

Elongation vs Break LoadTension Fatigue

| Diameter | Circle | Weight | Breaking Strength | |||

| mm | inch | inch | LBS/100FT | KGS/100M | lbs | ton |

| 4 | 1/8 | 1/2 | 0.7 | 1.0 | 2860 | 1.30 |

| 5 | 3/16 | 9/16 | 1.3 | 1.8 | 4900 | 2.20 |

| 6 | 1/4 | 3/4 | 1.6 | 2.4 | 7000 | 3.19 |

| 7 | 9/32 | 21/25 | 2.3 | 3.2 | 8800 | 4.00 |

| 8 | 5/16 | 1 | 2.7 | 4.0 | 13000 | 5.90 |

| 10 | 3/8 | 1-1/8 | 4.0 | 5.6 | 19600 | 8.90 |

| 11 | 7/16 | 1-1/4 | 4.2 | 6.2 | 23800 | 10.80 |

| 12 | 1/2 | 1-1/2 | 6.4 | 8.9 | 30400 | 13.80 |

| 14 | 9/16 | 1-3/4 | 7.9 | 11.8 | 39900 | 18.10 |

| 16 | 5/8 | 2 | 10.2 | 15.2 | 46500 | 21.10 |

| 18 | 3/4 | 2-1/4 | 13.3 | 19.8 | 64300 | 29.20 |

| 22 | 7/8 | 2-3/4 | 19.6 | 29.2 | 88500 | 40.20 |

| 24 | 1 | 3 | 21.8 | 32.4 | 107800 | 49.00 |

| 26 | 1-1/16 | 3-1/4 | 27.5 | 40.9 | 123200 | 56.00 |

| 28 | 1-1/8 | 3-1/2 | 31.9 | 47.5 | 142400 | 64.70 |

| 30 | 1-1/4 | 3-3/4 | 36.2 | 53.9 | 165000 | 75.00 |

| 32 | 1-5/16 | 4 | 41.8 | 62.2 | 184000 | 83.60 |

| 34 | 1-3/8 | 4-1/8 | 45.0 | 67.0 | 202900 | 92.20 |

| 36 | 1-1/2 | 4-1/2 | 51.7 | 76.9 | 222200 | 101.00 |

| 40 | 1-5/8 | 5 | 63.5 | 88.0 | 268400 | 122.00 |

- Blog