They are regularly used for securely tying boats and ships to docksISTOCK On your way dock, the mooring ropes are what hold a boat or ship in place and keep them from drifting out to sea. Have you ever thought, how do these robust ropes manufacture? This time we will dive into an interesting process of making mooring ropes! Jinli is here to help us.

Steps to Make Mooring Ropes:

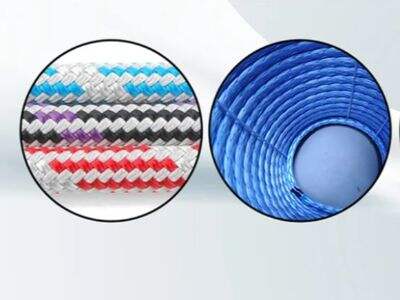

Well, the process starts with detailed planning. If you are a engineer, the rope is what people like me design and think carefully about how strong they should build them with knowing that steel will work better in some applications than polyester. This is impossible very important because the ropes have to bear heavy boats. Once the design is complete, it's time to get down and actually make some ropes. It takes fibers — or in the language of this lab, tiny chunks off a single roll of plastic that are twisted together into strings. The fibers of this coconut yarn are twisted together resulting to a thicker thread. Lastly, the yarns are twisted again to form a whole and finished rope that can adequately hold an anchor line for safe boat mooring.

How Mooring Ropes are Made:

Opting to make mooring ropes and recovery rope is a task that ought not be made gently since it requires very certain operate and all the good details are essential. We at jinli ropes the leading company manufacturing these kinds of rope use special machines and workers who are highly skilled to create only the highest quality ropes. Every detail from the first design to final inspection prior if working ropes are carefully examined by our experts. This guarantees that the ropes are durable and secure to use with boats as well as ships.

Materials for Mooring Ropes:

The material composition of the different types of mooring ropes and Safety Rope And Net are chosen for specific applications associated with each type. We employ nylon, polyester and polypropylene at Jinli. Every single one of these materials has its own attributes that allow themselves to be better at specific things. Nylon ropes, for instance, are known to be both sturdy and slightly elastic; this elasticity can give a little when the boat suddenly lurches forward or backward in addition to being very strong. In contrast, polypropylene ropes are very light weight and easy to handle which adds flying pleasure than any type of your vehicles as well you can use them outdoor with the same function without worrying about sunlight damage.

Testing Mooring Ropes:

We test our ropes on Jinli especially Fishing Rope And Net. The quality of those extension is subjected to various ways and always are tried setting on a test page. This includes a visual inspection of the ropes to verify there are no defects. We also conduct tensile tests to determine the weight of loads that a rope can carry before it snaps. Throughout the entire process of ropes are made, checks at regular intervals should be done to catch issues before those ropes are finished This means that our ropes are of the highest quality.

Rope making Quality standards:

Making the ropes is a stringent rule and regulation. In Jinli, we strictly follow the standards that are laid down which include ISO 9001 and ISO 14001. They are designed to ensure our ropes can be safely used by people and that they are produced in an environmentally good manner. We adhere to these so that our ropes are strong, durable and ethical.